HAWSHI AC Welding Machine Spot Welding for Stainless Steel Welder Industrial Powerful Welding Machine

Detailed Description Of The AC Welding Machine

The AC Spot Welding Machine stands out as a pinnacle of efficient welding technology, harnessing the power of alternating current for precision spot welding operations. This versatile solution effortlessly welds various metal materials, from robust carbon steel to sleek stainless steel and copper, making it a prime choice for automotive manufacturing, home appliances, and electronics industries. Its advanced control technology guarantees stable welding processes, ensuring impeccable weld quality and exceptional reliability. Designed with user convenience in mind, the machine features an intuitive control panel, enabling seamless operation in diverse working environments. Additionally, its exceptional energy efficiency not only lowers operational costs but also aligns with sustainable practices, making it the ultimate choice for industrial welding needs.

Features Of The AC Welding Machine

Efficient AC Welding:

The AC Spot Welding Machine is designed for efficient spot welding tasks, utilizing alternating current technology. It excels in providing accurate and consistent welds on a variety of metal materials, including carbon steel, stainless steel,etc. Its precision in welding makes it a reliable choice for industrial applications where high-quality joints are essential.

User-Friendly Controls:

Featuring intuitive controls, this machine ensures ease of operation. The user-friendly interface simplifies the welding process, allowing operators to work efficiently and effectively. Its ergonomic design and straightforward controls enhance productivity, making it ideal for both experienced welders and those new to the process.

Versatile Industrial Application:

The AC Spot Welding Machine finds its application across diverse industries, including automotive, electronics, and manufacturing. Its versatility allows it to handle various materials and thicknesses, making it a valuable asset in assembly lines and production facilities. Its ability to deliver precise, reliable welds consistently positions it as a key tool for numerous industrial tasks.

|

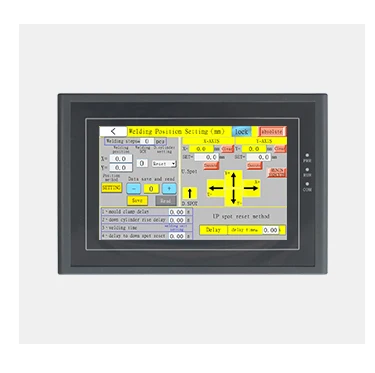

Intelligent welding control system

Intelligent Touch Screen Controller

Input and read welding parameters.

|

|

Raw materials made to standard

Thicker Copper Plate or Copper Belt To ensure stable conductivity in welding

|

|

Custom processing of electrodes

Customized Electrodes which will be suitable for Welding material like steel, aluminium, silver, stainless Steel, and nickel steel.

|

Specifications Of The AC Welding Machine

| Model |

Input

Voltage |

Input

Power |

Output Current |

Pressurization |

Electrode

Stroke |

Closure |

Platform

Distance |

Electrode

Distance |

| V |

KVA |

A |

kg |

mm |

mm |

mm |

mm |

| WL-S-3K |

220 |

10 |

5000 |

200 |

50 |

65-115 |

- |

145-165 |

| WL-S-5K |

220 |

10 |

6000 |

200 |

50 |

65-115 |

- |

145-165 |

| WL-S-10K |

220 |

10 |

8000 |

200 |

50 |

65-115 |

- |

145-165 |

| WL-S-16K |

380 |

16 |

10000 |

300 |

80 |

- |

- |

- |

| WL-S-25K |

25 |

12000 |

300 |

80 |

- |

- |

- |

| WL-S-35K |

35 |

16000 |

350 |

80 |

- |

- |

- |

| WL-S-50K |

50 |

19500 |

500 |

80 |

- |

- |

- |

| WL-SP-25K |

25 |

12000 |

300

|

80 |

145-225 |

250 |

320-420 |

| WL-SP-35K |

50 |

16000 |

350 |

80 |

145-225 |

250 |

320-420 |

| WL-SP-50K |

50 |

19500 |

500 |

80 |

145-225 |

250 |

320-420 |

| WL-SP-75K |

75 |

24000 |

1000 |

100 |

130-230 |

260 |

490-540 |

| WL-SP-100K |

100 |

34000 |

1000 |

100 |

130-230 |

260 |

490-540 |

| WL-SP-150K |

150 |

40000 |

1000 |

100 |

130-230 |

260 |

490-540 |

| WL-SP-200K |

200 |

50000 |

1500 |

100 |

130-230 |

260 |

490-540 |

| WL-P-75K |

75 |

24000 |

1000 |

100 |

130-230 |

260 |

- |

| WL-P-100K |

100 |

34000 |

1000 |

100 |

130-230 |

260 |

- |

| WL-P-150K |

150 |

40000 |

1000 |

100 |

130-230 |

260 |

- |

| WL-P-200K |

380 |

200 |

50000 |

1500 |

100 |

130-230 |

260 |

- |

| WL-P-300K |

380 |

300 |

75000 |

2000 |

100 |

130-230 |

260 |

- |

Application And Samples Of The AC Welding Machine

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!